The goal of the project is to ensure the constant production of reliable and ecological heat for Brno, to increase the production of energy on the local source and, last but not least, to complete its greening. Our long-term effort leads to the application of technologies that increase the use of renewable resources in line with today´s demands and trends...

Unroll

The goal of the project is to ensure the constant production of reliable and ecological heat for Brno, to increase the production of energy on the local source and, last but not least, to complete its greening. Our long-term effort leads to the application of technologies that increase the use of renewable resources in line with today’s demands and trends including wood chips, which we want to use in the new heat source. The reconstruction of the facility is part of the overall plant modernisation at 60 Obřanská Street. This source was launched in 1974 and the current boilers only have a permit to operate until 2022. It is necessary to begin with their replacement.

Thanks to the implementation of the new heat source, we will increase the reliability of household heat and electricity supplies. Heating with wood chips is not only cheaper and more economical, but also safer. No one can turn off the fuel supply, as is the case with natural gas. The new solution will guarantee fuel diversity increase and ensure the supply of energy to the population in emergency situations, such as political and economic changes. The new heat source is our response to these potential impacts, because fuel diversification is the only way to prevent possible fuel supply problems.

We have been interested in promoting sustainable development, which prefers a more environmentally friendly resource. The construction of this new heat source will allow us to replace fossil fuels with local renewable ones. The biomass will be burned using high tech filters, which means another step towards cleaner air. The new wood chip boiler flue gas discharge will be ensured by the existing 217.5 m high chimney. Thanks to the renovation, the operation will not only be fully compliant with the strict limits in the Czech Republic, but also in the EU.

We strive to be a socially responsible company, using our resources with maximum efficiency. With the full use of state-of-the-art technologies and advanced environmental solutions, we are expanding the production of heat and electricity in a cogeneration manner by implementing another type of primary fuel. This process is the most efficient way to transform the primary energy of fuel into usable energy. The designed solution will also enhance the flexibility of the entire Brno-Sever heat resource.

Local residents don’t have to worry about increased traffic load during wood chip transportation. The supply will be limited to once daily via train. From May to September, the source will be stopped altogether, which also means a reduction in the transport of trains with wood chips. The area will receive a connection of the new housing to the central supply, other local project support and many further activities. During the redevelopment of the heat source we will not only improve the complex interior, but also the surrounding public spaces as well.

In energetics, we use the term biomass for matter of organic origin such as plant residues produced by forestry and logging, which can be used as fuel. Our supplier is the Forests of the City of Brno. Wood chips have many advantages, of which the main advantage is renewability.

Unroll

In energetics, we use the term biomass for matter of organic origin such as plant residues produced by forestry and logging, which can be used as fuel. Our supplier is the Forests of the City of Brno. Wood chips have many advantages, of which the main advantage is renewability. There will always be enough wood chips in the Czech Republic. They will never be depleted. Moreover, heating with wood chips is cheaper and environmentally friendly. This fuel must be made from uncontaminated wood waste with less than 60% humidity.

Jan 13, 2025

To rid the South Moravian metropolis of its dependence on gas for heating as quickly as possible. One of the pillars of this strategic task is the construction of a new wood chip boiler to replace the original fossil fuel-fired at the Brno-sever heat plant, originally fired by fuel oil and gas, which has been in operation since 1982. The new technology combines the production of heat and electricity by burning wood or biomass, and as a result will supply almost 15 percent of the energy to the central heating system.

More info

To rid the South Moravian metropolis of its dependence on gas for heating as quickly as possible. One of the pillars of this strategic task is the construction of a new wood chip boiler to replace the original fossil fuel-fired at the Brno-sever heat plant, originally fired by fuel oil and gas, which has been in operation since 1982. The new technology combines the production of heat and electricity by burning wood or biomass, and as a result will supply almost 15 percent of the energy to the central heating system. Construction began in June 2023 and has progressed significantly in the past year. Construction is well underway and the first results are being seen. "Demolition work includes the removal of the original bridge piping that prevented the construction of the new chipping warehouse. A new power bridge has been constructed at the front of the site and the utilities on site have been relocated. A part of the boiler room received a new facade, which replaced the old, unsatisfactory glass cladding," said Radka Mistrová, spokesperson for Teplarny Brno.

Inside the boiler room, construction work was underway, which included preparatory work for the installation of the boiler and turbine, which is already installed in the engine room. The turbine was manufactured directly in Brno by Siemens. The heaviest parts of the boiler had to be moved by heavy machinery across the open roof of the boiler room.

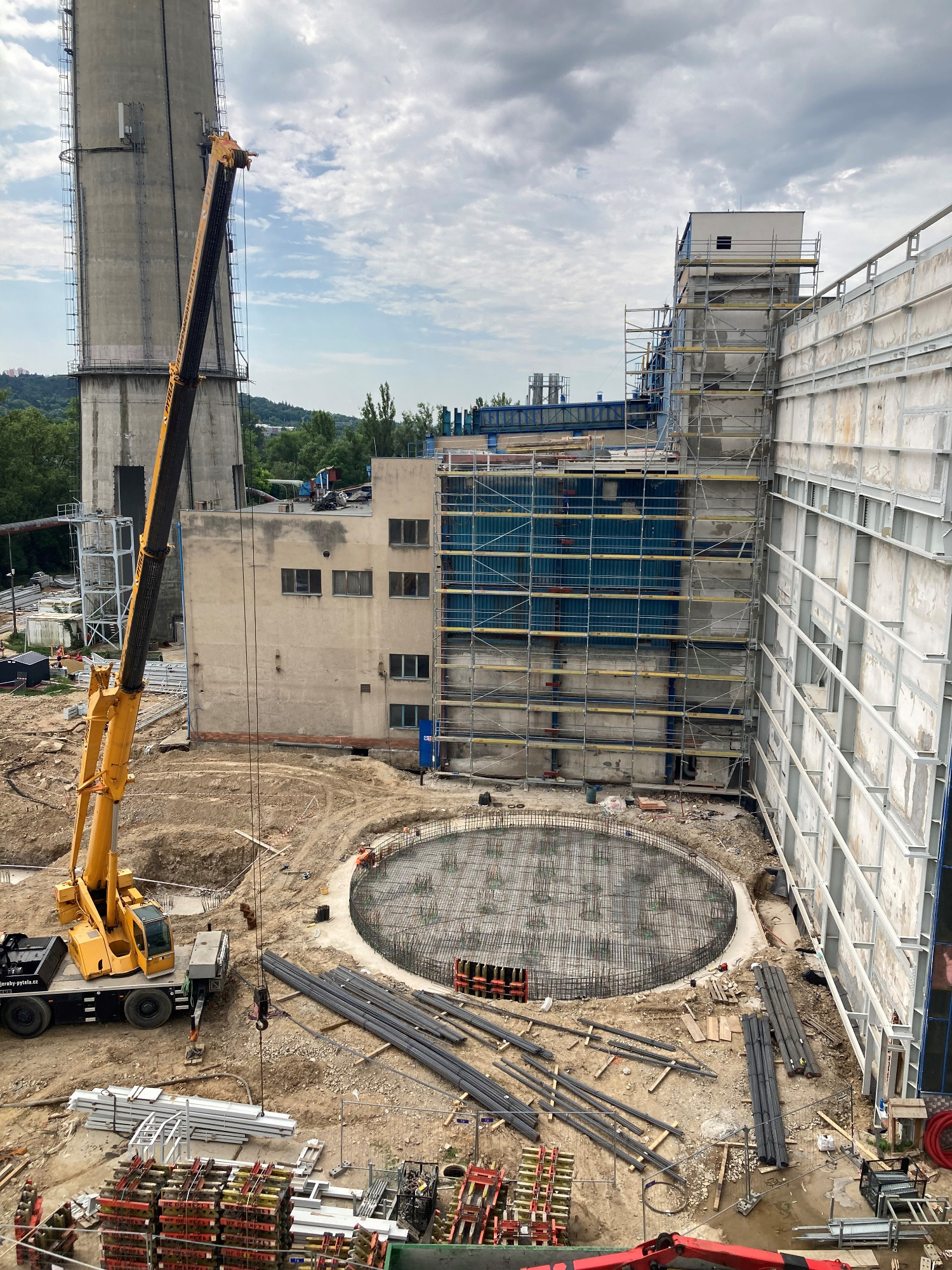

On the site of the demolished part of the old boiler house, a heating water accumulator with a capacity of 3,500 m³ is now being built to ensure efficient heat supply to the city's central supply network. Last spring, the reconstruction of the 217.5 m high chimney was completed, which will again be used to extract the flue gases from the new boiler. The chimney is the tallest structure in Brno, the ninth tallest chimney and the sixteenth tallest structure in the Czech Republic. The rough construction of a modern warehouse for a five-day supply of wood chips, which will be supplied by the Brno City Forests, is currently being completed. The transport of wood chips and ash will be carried out exclusively by rail. Therefore, the on-site railway siding, which was originally used for transporting fuel oil, is now being completely reconstructed. The most significant event for the construction of the new woodchip boiler was without a doubt the approval of the subsidy from the Modernisation Fund of the State Environmental Fund. Thanks to the contract that Teplárny Brno concluded with the State Environmental Fund, they can draw CZK 1.66 billion, which will cover more than 64 percent of the total cost, which amounts to approximately CZK 2.5 billion. The new boiler should start trial operation this year. The first heat supplies to Brno residents should start flowing in the autumn.

Nov 6, 2024

The oversized boiler parts were installed through the dismantled roof of the boiler room at the end of October. The largest piece (also called rear block) is 18.5 meters tall and it weights just over 50 tons.

More info

The oversized boiler parts were installed through the dismantled roof of the boiler room at the end of October. The largest piece (also called rear block) is 18.5 meters tall and it weights just over 50 tons. For this mission a crane with a maximum lifting capacity of 700 tons and a lift height up to 149.5 meters was used.

Although it was not as tall as the top of the Maloměřice chimney, all parts that needed to be relocated to the boiler room were placed successfully! Therefore, nothing now prevents the installation of the new boiler room roof and the ongoing assembly work inside.

Oct 4, 2024

Nové skladovací prostory pojmou zásoby paliva na minimálně 5 dnů. Díky prefabrikované výstavbě bude hrubá stavba skladu hotová již letos v zimě. S prvním návozem štěpky počítáme ve zkušebním provozu v topné sezóně 2025/2026.

More info

Nové skladovací prostory pojmou zásoby paliva na minimálně 5 dnů. Díky prefabrikované výstavbě bude hrubá stavba skladu hotová již letos v zimě. S prvním návozem štěpky počítáme ve zkušebním provozu v topné sezóně 2025/2026.

Ještě vloni stál ve východní části areálu provozu Brno-sever starý potrubní most, který původně sloužil pro přepravu mazutu coby paliva dnes již demontovaných kotlů. Na jeho místě nyní stavíme nový moderní sklad pro biomasový zdroj, který pojme až 10 390 kubíků štěpky. Zajistí zásoby paliva minimálně na 5 dnů dopředu, a to pro pokrytí období víkendů, svátků, ale i případných výpadků železniční dopravy, přes kterou k nám štěpku po kolejích budeme dopravovat. Z železniční vlečky v areálu ji pak navezeme do skladu přímo v kontejnerech za pomocí vysokozdvižného vidlicového vozíku. Plánovaný sklad je vybaven mostovým jeřábem s drapákem, posuvnými podlahami pro palivo, třídičem, drtičem a další technologií. Díky plné automatizaci pak štěpka poputuje na pásovém dopravníku v aktuálně požadovaném množství až ke kotli.

Aug 5, 2024

As part of our project, we have launched construction of a new heating water accumulator. This key infrastructure will stand on the site of the recently demolished old boiler house and will deliver significant improvements in energy efficiency and sustainability.

More info

As part of our project, we have launched construction of a new heating water accumulator. This key infrastructure will stand on the site of the recently demolished old boiler house and will deliver significant improvements in energy efficiency and sustainability.

The new accumulator, with a capacity of 3,500 m³, will be able to store water heated up to 95 °C. The ability to store heating water is essential to ensure a balanced and stable operation of the new woodchip resource. This will enable the heat supply to the thermal energy supply system (SZTE) network to be regulated efficiently with a capacity of up to 20 MW.

The project brings several significant benefits. It will enable better use of renewable energy sources, which is key to reducing greenhouse gas emissions and combating climate change. It will increase the energy efficiency of the whole system, leading to lower operating costs and better use of available resources.

The construction of the accumulator is an important step towards a more sustainable energy future. We expect the new accumulator to be fully operational in the coming months. Thank you to everyone involved in the project and helping us achieve our energy and sustainability goals.

Jul 29, 2024

In June, we informed you about the finalisation of the reconstruction of the Maloměřice chimney, which is the highest structure in Brno at a height of 217.5 m. We decided to use the chimney, which has not served its purpose since 2021, for a new ecological source of heat and electricity. The chimney has undergone a complete rehabilitation of its internal surfaces, and the heavily damaged crown has also been repaired. After reconstruction, it will serve its purpose again with a new stainless steel liner. Now it is just waiting to be connected to the new boiler technology.

More info

In June, we informed you about the finalisation of the reconstruction of the Maloměřice chimney, which is the highest structure in Brno at a height of 217.5 m. We decided to use the chimney, which has not served its purpose since 2021, for a new ecological source of heat and electricity. The chimney has undergone a complete rehabilitation of its internal surfaces, and the heavily damaged crown has also been repaired. After reconstruction, it will serve its purpose again with a new stainless steel liner. Now it is just waiting to be connected to the new boiler technology.

The contractor also handed over the detailed design documentation at the end of May, which is important for the proper continuation of the construction. This key milestone has also been successfully passed, and construction is well underway with the aim of starting trial operation in the 2025/2026 heating season.

Jun 7, 2024

As part of the construction of the woodchip boiler we started the reconstruction of the 217.5 m high chimney at the Brno-sever heat plant in Maloměřice. It is the tallest building in Brno, the ninth tallest chimney in the Czech Republic and the sixteenth tallest building in the country.

More info

As part of the construction of the woodchip boiler we started the reconstruction of the 217.5 m high chimney at the Brno-sever heat plant in Maloměřice. It is the tallest building in Brno, the ninth tallest chimney in the Czech Republic and the sixteenth tallest building in the country.

The chimney has not served its purpose since 2021. So that the chimney does not only have an aesthetic function, Teplárny decided to use it for a new ecological source of heat and electricity. Therefore, the chimney went through a complete remediation of the internal surfaces and also the heavily damaged crown of the chimney was repaired. After the reconstruction, thanks to a new stainless steel smoke flue, it will serve its purpose again and it is clear, that Maloměřice and Obřany will not lose their landmark for many years to come.

Dec 24, 2023

Positive ENERGY in the year 2024!

More info

Jun 12, 2023

On Friday 9 June 2023, Teplárny Brno ceremonially started the construction of a biomass source for burning woodchips at the Brno-sever heat plant. The combustion of woodchips will replace approximately 15% of natural gas consumption since 2025.

More info

On Friday 9 June 2023, Teplárny Brno ceremonially started the construction of a biomass source for burning woodchips at the Brno-sever heat plant. The combustion of woodchips will replace approximately 15% of natural gas consumption since 2025.

More information:

Apr 12, 2023

Teplárny Brno company carried out a compensatory tree planting in the Maloměřice and Obřany areas to offset the trees cut down during the construction of a new wood chip boiler at the Brno-sever plant. A total of 21 new woody plant were planted and we believe that they will contribute to the revitalization of greenery in this area.

More info

Teplárny Brno company carried out a compensatory tree planting in the Maloměřice and Obřany areas to offset the trees cut down during the construction of a new wood chip boiler at the Brno-sever plant. A total of 21 new woody plant were planted and we believe that they will contribute to the revitalization of greenery in this area. This step is part of our commitment to sustainable development and environmental protection. The planting was carried out by the company Public Greenery of the City of Brno and will now carry out post-planting care for a period of five years.

Feb 24, 2023

Yesterday was signed a contract with the supplier of a new biomass boiler for Teplárny Brno. The winner of the tender for the delivery of the project and building is a consortium of companies Škoda Praha and OHLA ŽS.

More info

Yesterday was signed a contract with the supplier of a new biomass boiler for Teplárny Brno. The winner of the tender for the delivery of the project and building is a consortium of companies Škoda Praha and OHLA ŽS. The construction of a wood chip boiler will ensure constant production of reliable heat and increase production from the existing source. The main goal is to diversify the fuel base and reduce dependence on natural gas itself. Work on the construction site is expected to start in April this year.

Photo: Marie Schmerková, Archive of the city of Brno

It is actually a reconstruction and modernisation of part of the current technological production source. Most major construction and assembly work will thus take place inside the existing boiler room building. The necessary dismantling and subsequent construction work will be carried out according to a specified plan, which is compiled, inter alia, on the basis of construction conditions set by state administration bodies. Short-term restrictions mainly concern the operation of the heating plant itself. The traffic will not be increased either.

Modernisation will not fundamentally affect the life of the city district. Most citizens are unlikely to notice the performed work.

Natural gas is still a fossil fuel, in contrast with wood chips, which is a renewable source of energy from local sources. The clear trend of energy concepts by the European Union, starting through the South Moravian region or city of Brno, is clearly ecology and increasing the share of renewable sources in the overall energy mix. Wood chips are also not burdened, for example, by the purchase of so-called emission allowances, the price of which has been extremely high in recent years. The installation of a wood chip source clearly means an ecological solution that meets the requirement for the use of renewable sources in central heat supply systems in large agglomerations.

In this context, it is good to mention the fact that the implementation of the wood chip source will diversify the fuel base. At present, natural gas is mainly used for the production of heat and electricity in Brno. Almost a third of the primary fuel will be replaced by the incineration of secondary waste in an energy recovery facility. In the future, wood chips will replace another significant, almost twenty percent, part of natural gas. This will significantly increase the energy security of district heating sources. The customer will not even notice a possible failure in securing some fuel types.

The existing installed boilers, which enabled the combustion of fuel oil or natural gas, have been in operation since the 1980s. The combustion of fuel oil was ceased in 2011. The boilers themselves, with a total output of almost 150 MW, are too large from today's point of view and their use is not efficient. In addition, they are already obsolete in terms of today's technical requirements.

Due to the operation of the central heat supply system in Brno, it is necessary to keep the installed power of the Maloměřice sources ideally at the level of 70 MW. In 2016, the company installed new modern gas boilers with an output of 30 MW. It is therefore clear that during the further modernisation of the source, it is simply not possible to shut down the old boilers. Another new source of about 40 MW needs to be built. The installation of a new boiler, therefore, means simply replacing the existing equipment with new, smaller and more modern ones, which will extend the life of the source and increase safety, especially in the area of heat supply for the city.

Wood chips are a renewable resource precisely because they are constantly replenished naturally. The bark beetle calamity is primarily a problem that concerns forest managers. However, it will still be managed in the forests and also in other stands. Forest companies will continue to fulfil their logging plans, and soft spruce wood will replace other wood species. It will still be necessary to provide pruning and testing to maintain public greenery. Before planting new stands, it will be necessary to remove a lot of stumps. Part of the area is afforested with fast-growing and more resistant trees. There will be enough usable material and the trade in wood and, therefore, also in wood chips will not stop. It can be assumed that the price will be acceptable in the future. We can only assume that the price of wood chips has not changed much in the last ten years. It was not affected by the increased demand at the time of adding wood chips to thermal coal or the current large amount of so-called calamitous wood.

As part of the preparatory work for the project, Teplárny Brno carried out a number of different surveys on the wood chip topic. They work closely with Lesy města Brna, a. s. The Ministry of Agriculture of the Czech Republic, Forestry Section, asked the Ministry of Agriculture of the Czech Republic to assess the current situation and future trends. In addition, the assessment was the result of cooperation with the Institute for Forest Management, the state enterprise Lesy ČR and the Ministry of Industry and Trade. All reports suggest that there will be enough wood chips in the near future.

The equipment will be selected to meet all of the strictest requirements for technologies used elsewhere in Europe for this type of boiler, which also imposes a legislative obligation to use the best available techniques (so-called BAT). The expected service life of the source will actually be 20 years, which can be further extended by quality maintenance.

The project for the construction of a new source will require an more than CZK 2 billion investment. The payback period should be around fifteen years.

All "operational" transport of not only the fuel, but also of the produced ash will exclusively take place by rail. This means that a train with 20 wagons will arrive at the site each day. We will use the train because it is an ecological form of transport that will help avoid 20 fully-loaded trucks on local roads.

No trucks, no dust. For comparison, at the railway station in Maloměřice, the Railway Infrastructure Administration handles approximately 1,000 railway wagons per day. One additional train will not significantly increase the load.

Unloading will take place "under the roof" and the fuel will be stored in a covered vacuum warehouse. It will be located as far away from the development as possible, on the border with the neighbouring area of the former cement plants. The wagons will be moved by electric lift. The wagon unloading will preferably take place in the morning, quickly and without unnecessary noise.

Wood chips are a natural material that theoretically may burn. This is in most cases due to longer storage times and heating due to wood decay. The warehouse in Maloměřice is designed for a maximum eight-day consumption: the wood chips will not lie "motionless" for more than one or two days. Therefore, decay cannot even occur.

However, the modern wood chip warehouse will of course be equipped with an electric fire alarm system and other systematic measures to eliminate the risk of fire.

Waste products will be stored in steel silos, which will be located on a steel structure. The building is positioned over the route of one of the tracks so as to enable the wagons to be filled as they pass through the building. Ash removal by rail will also only take place at most once a week.

The operation of the biomass boiler will not increase the noise load of the operation in Maloměřice and the surrounding area, which was confirmed by a special noise study.

Wood chips will be burned in the most modern boiler available. Also, all other facilities involved in the process of heat and electricity production will be at the highest level. The flue gases are led from the boiler to the electrostatic precipitator and then to the existing 217.5 m high chimney (no new chimney will appear). Fuel metering will be automatically controlled according to the load requirements of the boiler. The design of the boiler is made so that the generation of gaseous emissions is maximally suppressed.

The dispersion study, according to the requirements valid until 2020, confirmed that the combustion of biomass will not have an impact on the environment.

Wood chips are a renewable energy source with a significantly lower carbon content than fossil fuels. Biomass has a negligible SO2 concentration in the flue gas and a neutral CO2 balance.

We have also included continuous emission measurements in the project, the results of which will be able to be monitored continuously after commissioning, for example, on the websites of the city district or Teplarny Brno.

The dimensioning of the heating source is always related to current need. In the 1980s, the need for thermal energy to provide household heating was significantly higher than it is now, which was in line with the original output of the small metering source. One of the basic goals of the modernisation is to respond to the new situation on the part of customers and effectively reduce the installed capacity. The total power for the complete reconstruction, i.e., after installation of the wood chip source, will drop to 70 MW, i.e., to less than 39% of the original size. By no means is this an "oversizing" of the resource.

The company Teplarny Brno has always tried to closely work with the Brno Maloměřice and Obřany districts. Recent projects such as the connection of new housing to the central heat supply and the associated support of other investment projects, for example, in the form of land appropriation for the construction of a social services building and other city hall projects can be cited. Teplárny Brno continues to count on the support of selected projects within the Maloměřice and Obřany districts. They will look for suitable activities with representatives of the local town hall.

As part of the public presentation of the project in November last year, citizens of the city district mentioned a situation in which flue gases flowed from a gas boiler in low air layers. The explanation for this extraordinary situation is simple – the short-term flow of flue gases from hot water boilers during the inversion occurred in the autumn of 2016 during the trial operation and adjustment of newly installed gas boilers. The purpose of the test operation was primarily to adjust the combustion process and set the optimal technological parameters. This was a success, and nothing similar has ever happened again in connection with hot water boiler operations in Maloměřice since then. Moreover, in the case of a wood chip source, a similar situation cannot occur. The flue gases will be discharged via a 217 metre-high chimney.